Robotic Custom Solutions

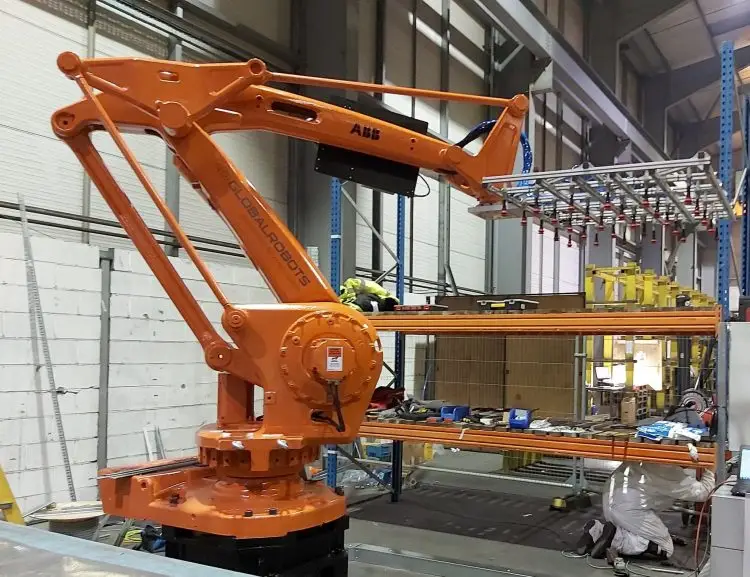

Phoenix can integrate the robot for dispensing operations, we can configure and customise them with end-of-arm-tooling, fixtures and safety enclosures. We help you to evaluate and select the most efficient and cost-effective robotic automation for your application and process.

The robot integrator will help with the integration of the robot cell, the user interfaces with process control systems, get an idea of the ROI, and after-sale support. It is the whole automation package.

Customised Automation Packages

Benefits Using Robotic Material Handling

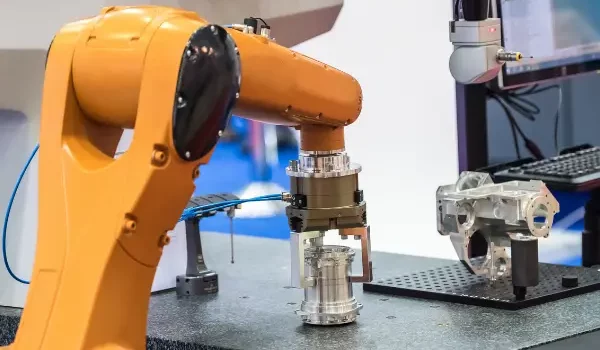

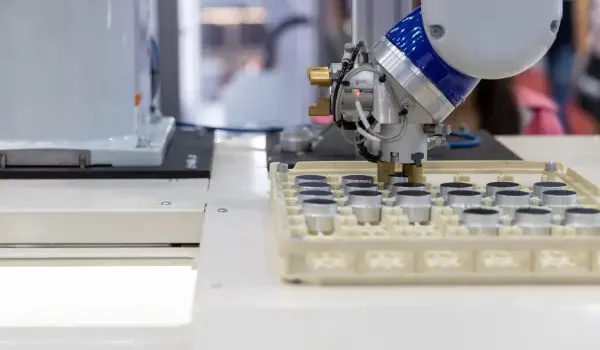

Robotic material handling systems enhance the efficiency of the production line, improve quality and speed. Also, the most common applications include sorting, machine tending, press tending, part transfer, case packing and palletising. Hence, any object of any size or shape can be handled by the robot by simply adjusting the robot programming and the end-of-arm tooling.

- High Quality & Productivity

- Improve production planning and reduces overtime

- Extremely reliable

- Reduce scrap and rework

- Less Labour Issues

- Easily programmed to handle multiple parts

- Robots can be re-deployed if production needs to change

Typical examples of Material Handling Robots

The common examples of material handling by robots include:

- The feeding of raw stock in the production line

- The loading and unloading of parts or products

- The stacking of cartons on pallets

- The majority of pick-and-place robots and also the 6 axis robots are equipped with internal sensors and industrial control systems which help them to perform operations with success.

Robotic Cost-Saving and Quick ROI

Robotic material handling systems tends to be a cost-saving and quick return on investment when you work together with a system integrator or robot integrator with vast expertise. Thus, the majority of the integrators can prove with real cases studies their robot integration projects. A robotic systems integrator will be happy to share with you their success with automation. Check Out our ROI Calculator Tool

But, let’s see what the experts in the robot industry are saying:

“The growth of industrial robots continues at an impressive pace worldwide,” says Junji Tsuda, President of the International Federation of Robotics. “Key trends such as digitalisation, simplification and human-robot collaboration will certainly shape the future and drive forward rapid development.”, IFR

Robot Integrator for Robotic Material Handling Cell

ready to build a Robotic Material Handling Cell?

We build partnerships with our clients and we provide Customised Automation Packages.

Phoenix’s extensive automated painting experience can help you overcome any challenges.

Looking for more related articles? Check out some of our other top quality content below.