Salary Survey: Skilled worker shortage vs robot manufacturing

This is a clear overview of the skilled worker shortage and how it affects robot manufacturing companies, with data from salary surveys and industry trends:

Robot Manufacturing Companies

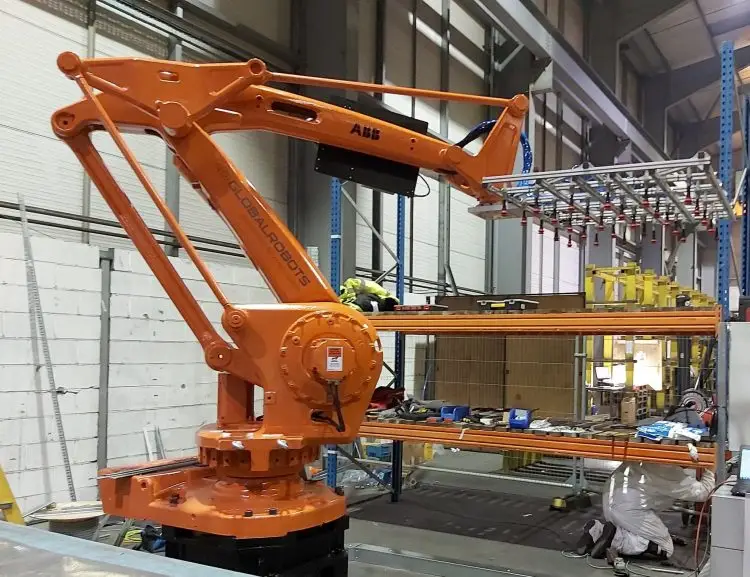

Manufacturing robots refer to a common practice of automating repetitive tasks across the manufacturing process. Therefore, the objective of robot manufacturing companies is to reduce manual errors, increase production efficiency, and save costs. Although there are many manufacturing robots for sale, not all of them are suitable for the specific automation tasks that a company wants to achieve.

In fact, one missing factor in industries is the lack of leadership or management skills and automation knowledge. Despite these challenges, there is still confidence in the manufacturing sector to fill the gap with their own workforce based on on-the-job experience.

“In 2023, there were 541,302 robots installed, a 2% decrease from the record 552,946 in 2022. For the third year, installations exceeded 500,000 units. The automotive industry regained its status as the largest customer, accounting for 25% of installations, while the electronics sector dropped to 23%. The metal and machinery sector increased its share to 14%, followed by plastics and chemicals at 4% and food and beverage at 3%. Additionally, 17% of installations lacked customer industry information.” IFR Robotics Report.

Salary Survey: Skilled worker shortage, challenges

It is true that industrial robots are assisting manufacturers because project managers oversee fewer employees, but this will not resolve all management skill issues. In fact, there is a shortage of robotic automation skills required for a successful automation project.

1. Current Skilled Worker Shortage

Manufacturing Sector Reality:

- A global shortage of skilled labor in welding, machining, assembly, and maintenance roles.

- Automation engineers and robot programmers are also in short supply.

Key Drivers of Shortage:

- Aging workforce: Many experienced technicians are retiring.

- Lack of young entrants: Manufacturing isn’t seen as an attractive career path.

- Rapid tech adoption: Robotics and automation demand outpaces training pipelines.

2. Salary Survey Trends

Robot Integration Engineers & Programmers:

- UK average: £40,000–£60,000/year, senior roles £70k+.

Welders and Skilled Fabricators:

- UK: £30,000–£40,000/year (experienced MIG/TIG welders higher).

Automation Maintenance Technicians:

- UK: £35,000–£50,000/year; France similar but slightly lower.

Observation: Salaries are rising 6–12% annually in automation roles due to scarcity.

3. Challenges for Robot Manufacturing Companies

High Competition for Talent:

- OEMs, integrators, and end-users all competing for the same pool of programmers and engineers.

Project Delays:

- Lack of skilled staff can delay integration timelines, increasing costs.

Training Burden:

- Companies invest heavily in in-house training to upskill staff because graduates lack industry-ready experience.

Retention Issues:

Skilled automation engineers are frequently poached by competitors.

4. How Robot Manufacturers Are Responding

Raising Salaries & Offering Perks:

- Flexible working, bonuses, fast-track career development.

- Investing in Training Academies:

- ABB, KUKA, FANUC offer certification programs.

Collaborating with Colleges & Universities:

- Apprenticeship programs to create a pipeline of robot programmers.

- Increasing Use of Simulation & Offline Programming:

- To reduce reliance on physical commissioning and speed up projects.

5. Robotics as a Solution to Shortage

Automation Filling the Gap:

- Robot adoption accelerates because of labor scarcity, especially in welding, palletizing, and painting.

Trend:

- Companies invest in robots to replace repetitive/manual jobs and redirect scarce human talent to programming, maintenance, and supervision.

Get peace of mind with Robot Automation

All plants have some form of robotics in their facilities, robots offer peace of mind because they produce high-quality work. Therefore, improving productivity.

They can also be predictable allowing employees to focus on other tasks. In fact, training and keeping the operators are more expensive than maintenance and the programming of the robots.

One more factor to consider is that they can be reprogrammed to perform other applications and refurbished to extend their useful life by providing proper maintenance.

In the following chart, we can see the main benefits of robotics in manufacturing. In this survey productivity is the highest robotic value for manufacturing.

Robot Integrator companies provide training to the operators and we are helping employees to start in automation.

Stay Connected

More Updates

The future of Robotic Automation Systems

The future of robotic automation systems is here with new technologies. It could be the start of a new era of working with robots cooking, robot serving food, robot surgery, or what about robots in the construction, lawyers, architecture design? Who knows what else we will hear about working with robots in the near future!

Can Robot milling replace a traditional CNC machine?

Robot milling can now replace a machine tool in certain applications, bringing a high level of flexibility to use different tools in the 3D space. Robots are capable of producing the highest quality complex and unusual geometries parts. For example, robotic milling systems can have flexible tooling for specific material removal.

Why you should invest in robotics & robot automation?

Robot automation & robotics equipment are easier to calculate the Return on Investment (ROI) than when you are investing in a share or stock market.