Industrial Robots for Any Robotic Application

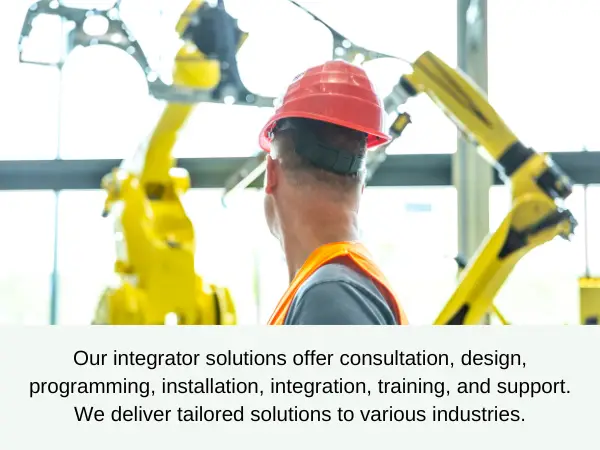

Industrial robots for all robotic applications. Our robot integrator solutions provide consultation, design, programming, installation, integration, training, and support for diverse industries.

Know what we do best

Our Robot Integration Services

Our Services

Are you looking to buy a robot but are unsure which brand to purchase? There are many robots for sale, including new and reconditioned ones. Phoenix can guide you in choosing the best option that meets your needs.

In addition, we can help you select the appropriate manufacturing systems for your needs, including designing and manufacturing robotic cells, as well as installation and commissioning.

Robot Integrator & Robot Cell Design

Our experts will be pleased to assist you in getting the best out of your robotic cell project and system integration.

Programming Robotic Arms and Simulations

Programming robot arms is a primary concern for a reliable robotics integrator when designing a cell.

Robot training courses for ABB, KUKA, and FANUC

We customize our robotics training courses for a quicker and more efficient launch, saving time and resources.

Our Robot Integrator Solutions

Robot integrator solutions typically refer to systems or services provided by companies that specialize in integrating robots into various industries. These solutions often involve designing, implementing, and maintaining robotic systems tailored to the specific needs of a business or manufacturing process.

- Consultation: We’ll listen and understand your needs, and provide expert guidance on the best robotic solutions.

- System Design: We’ll design the layout of robotic cells or production lines, and select suitable robotic arms, end effectors, and peripheral equipment.

- Programming: We’ll write and test software code to control robot movements and interactions with other equipment or products.

- Installation: We’ll set up the robotic systems in your facility, mount the robots, install safety measures, and integrate them with your existing machinery or infrastructure.

- Integration: We’ll connect robots with other components of the production process, such as conveyor belts, sensors, or computer systems, to ensure seamless operation and data exchange.

- Training: We’ll provide training programs for your employees to operate and maintain the robotic systems safely and efficiently.

- Support and Maintenance: We offer ongoing technical support and maintenance services to keep your systems running smoothly and address any issues that may arise.

Robot integrator solutions can include:

Most Popular Industrial Robot Manufacturers

Our company collaborates with the top robot manufacturers to provide affordable solutions for both new and refurbished robots. Whether you need a single robot or complete end-to-end integration, we can help you get the maximum value for your investment. As a result, we highly recommend consulting with us before making any purchases to make the most of your investment.

FANUC Robots

FANUC robots are extensively used in diverse industrial applications like automotive, aerospace, food, and pharmaceutical packaging. They are famous for their reliability, making them a favorite of manufacturers and assembly lines around the world.

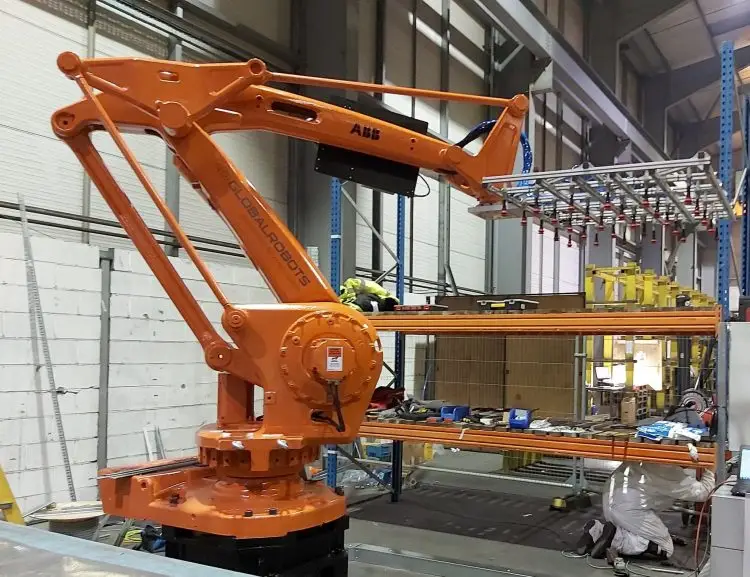

ABB Robots

ABB robots are used in different industries such as automotive, food, pharmaceuticals, and electronics to perform tasks like assembly, welding, painting, material handling, dispensing, palletizing, and packaging. They are renowned for their reliability and durability.

KUKA Robots

KUKA robots are versatile for industrial processes, customizable in arm length, payload, speed, accuracy, and adaptability, with a positive impact on industries such as automotive, aerospace, electronics, and food and beverage.

TOP Industrial Robots

Some of the most popular industrial robot manufacturers that have taken the market by storm include the likes of ABB, Fanuc, Kawasaki, Yaskawa, Kuka, and Universal Robots. These top-tier brands have been able to set the pace for others in the industry by consistently creating innovative products that meet up with the required standards and also, availing them at affordable prices. Therefore, it is not surprising that they are sought after by several industries and continue to maintain an excellent reputation for delivering the best quality.

Some of Our Projects

Phoenix Control Systems specializes in integrating industrial robots and control systems across various sectors. Additionally, we assist in selecting the appropriate manufacturing systems for your requirements, from design and manufacturing to installation and commissioning. Moreover, our team of experts is delighted to support you in maximizing the potential of your robotic project for any application. Please take a look at some of our recent projects below.

Robot Entertainment Industry

welding robots

Robotic Trimming

Robotic Palletising

What types of robotics applications are you hoping to automate?

When purchasing industrial robots, several factors should be taken into consideration. For example, the robot’s payload capacity, reach, and speed, as well as the type of robotic application it will be used for. Moreover, it is also important to assess the robot’s accuracy, repeatability, and flexibility, as well as its control system and communication capabilities.

Additionally, you should consider the level of training and support required to operate the robot effectively, as well as the cost of maintenance and repair. However, you may also want to compare the features and benefits of different models and brands, as well as the availability and cost of replacement parts.

By carefully evaluating your needs and conducting thorough research, you can choose an industrial robot that will meet your requirements and provide a strong return on investment for your business.

Things to consider when purchasing an Industrial Robots

The number of robots needed depends on the operation’s scale, automation level, budget, and potential benefits. Therefore, it is advisable to consult experts to determine the ideal number for your needs.

Different robots are made for different tasks such as welding, painting, and packaging. Therefore, Identify your needs and consider factors like size, speed, accuracy, environment, and cost. Consult a robot integrator for expert help.

One approach to designing a robot cell is to use the lean manufacturing principles. This involves minimizing waste, eliminating unnecessary movement, and optimizing space usage. Additionally, the type of robot being used and the tasks it will perform can also impact the layout design.

Shorter manufacturing processing times save costs, increase capacity, improve quality, and satisfy customers. Therefore, this requires streamlining, optimizing equipment and processes, as well as robot automation.

Loading and unloading time in manufacturing can cause bottlenecks, longer lead times, lowered productivity, and higher costs. To improve manufacturing efficiency, use robotic automation, continuous improvement, workforce planning, and training to reduce manual handling and cycle times.

The number of parts affects robot integration. Therefore, low quantities can be done manually, while high volumes require efficient robot work. Moreover, handling many types of parts impacts programming and complexity. The number of part types is important in production.

Most popular Robotic Applications

What manufacturing process would you like to automate?

As experts in production and robotic automation, we understand the importance of streamlining manufacturing processes to increase efficiency and reduce costs. However, you may not be certain about how to approach or inquire about a specific manufacturing process that you want to automate. Perhaps there is a production phase that you feel could be fully or partially automated to improve productivity, save time, and reduce errors. Or, you may need more understanding of the types of robotic applications available in the market to make better decisions.

By automating certain manufacturing processes, you can free up manpower to focus on other important aspects of the business. Therefore, whether it is the assembly line process, packaging, or something entirely different, we are here to offer our assistance in identifying potential areas for automation. Additionally, we can also share our insights and best practices for successfully automating the manufacturing process.

Phoenix is a robot integrator. We will guide you throughout the consultation, implementation, or integration of industrial robots into your process.

How can you prove that your robotic applications will work?

Robotic applications need to be tested to make sure they work correctly and are reliable. Many steps are involved in designing, implementing, and using these applications.

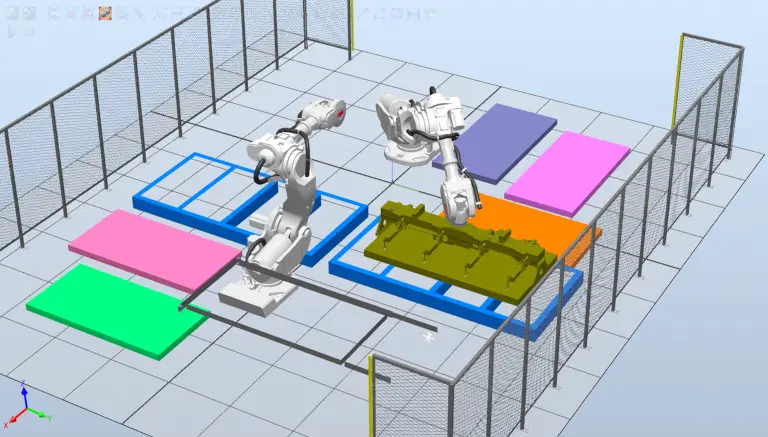

The importance of thoroughly testing and evaluating the capabilities of robotic applications in simulated scenarios cannot be overstated. This step is essential to ensure that the technology is both efficient and effective and will be able to fulfill its intended purpose once deployed. Such simulations allow for a detailed examination of various aspects of the technology, such as its functionality, accuracy, and reliability, as well as its potential limitations. By performing these tests beforehand, we can identify weaknesses and areas that need improvement, which in turn will facilitate the successful implementation of the technology and reduce the risk of potential setbacks or complications.

Therefore, it is crucial to dedicate sufficient time and resources to the simulation-based evaluation process, as this will pave the way for a smoother and more successful integration of robotic applications in a real-world setting.

At Phoenix, we are dedicated to helping our clients achieve their automation goals efficiently and effectively. With our extensive knowledge and experience, we can assist you in integrating a single cell or robots into your assembly line. Our team of experts understands that each manufacturer's factory processes are unique, and we work to identify the automation needs of your specific operation. By doing so, we can offer custom solutions that address your specific requirements, resulting in reduced costs and an efficient robots integration process. Through our collaborative approach, our customers not only save time and money but also save during the purchase of the robot(s). Trust us to be your partner in automation and see the benefits for yourself!

Types of Robotic Applications

In general, robotic applications can be categorized according to the tasks they perform which can range from very simple tasks such as transporting materials from one place to another, to more complex tasks such as performing surgery with the utmost precision.

Some common robotic applications include working in manufacturing lines, assisting with assembly, conducting research in hazardous environments, exploring space, and providing assistance to individuals with disabilities. In addition, robots are increasingly being utilized in fields such as agriculture, law enforcement, and education. Ultimately, the possibilities for robotic applications are endless and will largely depend on the needs of various industries and individuals in our society.Click below to learn more.

Our design for the Robotic Applications includes Robotic Simulation

As part of our robotic integration packages. One key aspect of our design process is the use of advanced robotic simulation. This allows us to model and test our designs in a virtual environment, ensuring that they are optimized for real-world conditions and able to perform at the highest levels of efficiency and accuracy.

The use of robotic simulation allows us to identify and address potential issues early on in the design process, reducing the risk of costly errors or delays down the line. By combining expert insights with the latest simulation techniques, we are able to deliver exceptional robotic applications that exceed expectations and set new standards for performance and reliability.