Industrial Robotic Arms for all Manufacturing Sectors

We are expert robotic integrators and can confidently provide affordable industrial robotic arms as well as seamless robotic integration.

What we can do for you

Starting with Industrial Robotic Arms

There are two types of robotic’ investments. When investing in a brand new robotic arm or reconditioned robots. In both cases, you need to bear in mind the additional costs involved. Let’s discuss in more detail what else is involved with robots and how we, as robot integrators, can help you to save time and costs.

01

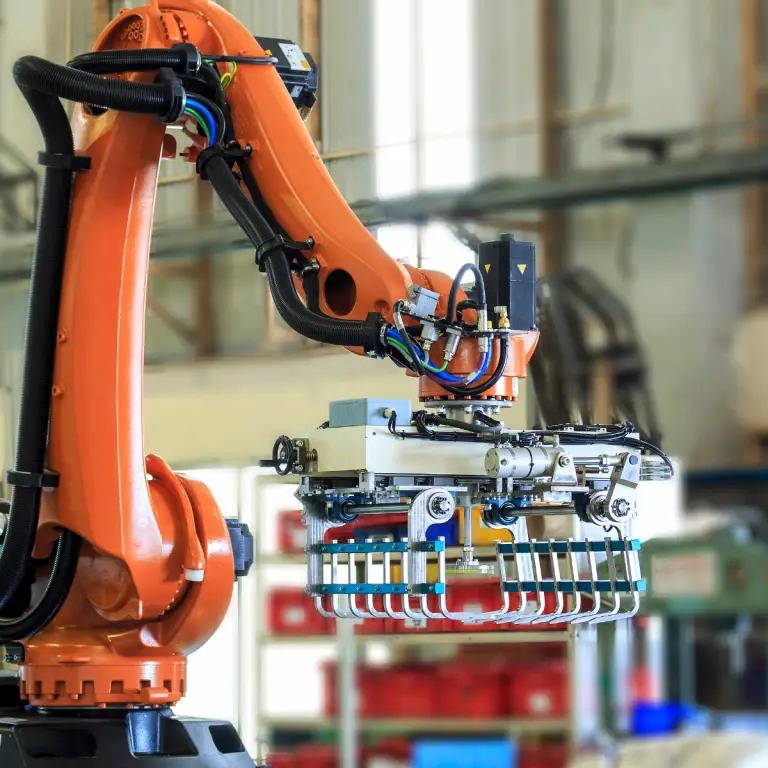

New Industrial Robotics Arms

First, brand new robot, when investing in a new robotic arm, you need to bear in mind the additional costs involved. For example, additional automation equipment such as gripper, turntable, safety, and control panel just to mention a few.

Car factories tend to keep production running to keep pace with the demand. Thus, this sector focuses on new robotic arms to work in a diverse of assembly lines robots. For example, spray painting robots, robotic welding, dispensing robots, milling, and cutting robots just to mention a few.

Approximate Lead time

Contact the robot manufacturer to know the lead time to deliver the robot if you want to buy new robot(s). Bear in mind, they are taking more than usual to deliver the robot.

02

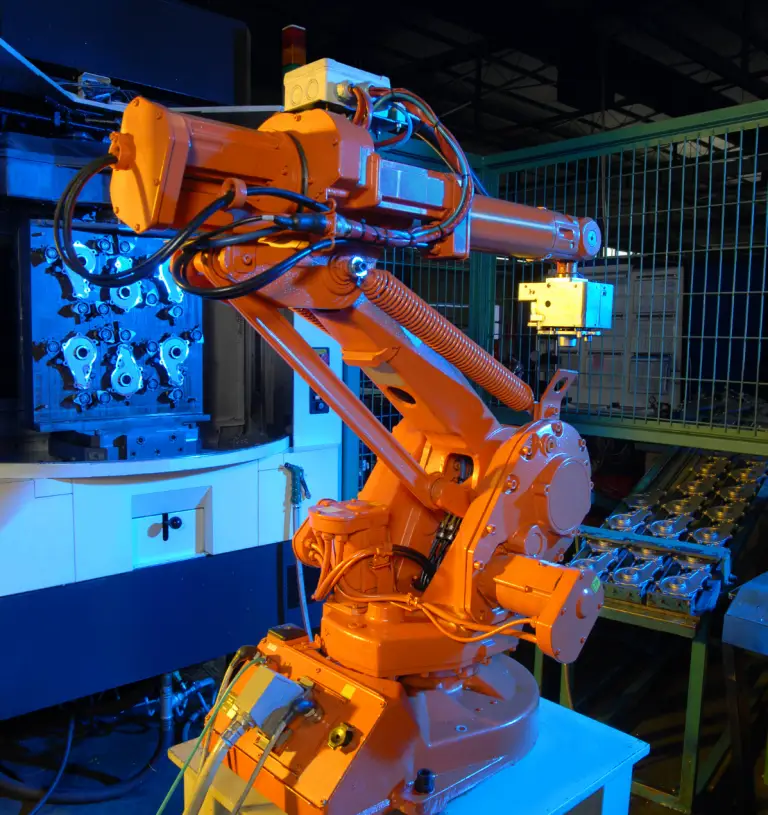

Reconditioned Robots

When it comes to planning for the future of a company, There is a balance between planning for the future and understanding the future needs of the company. However, the budget tends to be a key factor, if you are just starting in robotics and your budget is tight, why not try reconditioned robots? You can get a certified used robot for half the price of the new robot. However, that doesn’t mean that you have to compromise on the quality of your robotic machinery. So, why not consider reconditioned robots to take your company to the next level?

Approximate Lead time

The approximate lead time for reconditioned robots is between 8 to 10 weeks. Contact an integrator before you buy your robot(s).

03

Robotic Integration

To understand the process of robotic integration safety should be a top priority when choosing equipment such as sensors, guards/cells, locks, and vision. Additionally, installing an industrial robot requires a high-quality industrial control panel. It is recommended to seek the services of a robotic system integrator who can design and build a system based on the company’s needs and growth.

What Phoenix does for you?

Phoenix offers all robot services, including integration, design, installation, programming, and training. We work with well-known brands in the industry and are experienced in all robot brands.

Reconditioned Robots. Is this something worth considering?

In short, Yes! One of the big advantages of using refurbished robots today is their very competitive price point. You can find so many varieties of used robots for sale but bear in mind the condition of the robot.

Cost-Effective

Good return on investment in comparison to the amount invested.

Certified Robots

Certification is a guarantee of high standard procedures

Affordable Prices

Robot prices had come dome during the last years

Lead-Time

Better lead time delivery than new robots

Reliable Robotic Integration

Find Your Robot Integrator

Phoenix is a company that helps with industrial automation. We have lots of experience putting robots into projects. If you're considering buying a used robot arm, we have some guidelines that will help you choose the right one.

Our Robotic Integration Services

Why Start with Reconditioned Robots?

For this reason, using a reconditioned robot makes perfect sense for companies taking their first steps into robotic automation. This allows the company to gain experience without having to pay a heavy premium. However, it’s important to keep in mind that choosing the right robot with the guidance of a system integrator is crucial. The integrator will have extensive experience encompassing a variety of previous robotic projects to draw on.

Additionally, we will discuss the essential elements to consider when deciding to buy a robotic arm and automate your process.

Learning path, it is crucial to consider the following before purchasing a reconditioned robotic arm:

The following factors should be considered before purchasing a robot:

- Consider the robot version and controller, as hours of operation may not accurately reflect wear and tear for reconditioned models.

- Take into account the payload of the robot, which includes any additional loads.

- Consider the temperature of its operating environment.

- Consider how robot trajectory and operating programs will be taught: manually or generated offline.

- Check the robot’s motors and gearboxes from wrist to base for recent replacement due to their high cost and likelihood of failure.

- Additionally, don’t assume the robot comes with end-of-arm tooling.

Industrial Robotic Arms Tooling

We assist in choosing the right tools for your robotics application, including grippers, sensors, and vision systems, guaranteeing the best results.

Robotic Integration Best Practices: Essential Guidelines for Optimal System Performance

Robotic integration is an incredibly important aspect of modern technology. To ensure an efficient, effective and reliable robotic integration, some best practices must be followed.

First, it is vital that you have a solid understanding of your technology needs, as well as the capabilities of the robots you are planning to integrate. Secondly, select the right robot for your specific task and consider safety factors when choosing an optimal location for robotic operations. Thirdly, plan for all possible issues that could arise and identify backup plans to mitigate downtime. Finally, maintain open communication between all parties involved in the integration process to ensure everyone is on the same page and avoid unnecessary complications.

Through these best practices, you can ensure a seamless and successful robotic integration that will positively impact the productivity and profitability of your organization.

What to consider When looking into Robotic integration

When considering the integration of robotics into your operation, there are several important factors that you should take into account. Firstly, you will want to consider the specific goals that you hope to achieve with the implementation of robotics. This will help you to determine which types of robotics will be most useful for your needs, and how they can be best utilized to increase efficiency, reduce costs, and improve quality control.

In addition to your specific goals, you will also need to consider the financial costs of robotic integration, including the initial investment required for purchasing and installing the equipment, as well as the ongoing costs of maintenance, repairs, and training.

Other important factors to consider include the level of automation you need, the scalability of the robotics system, and the potential impact on your workforce and workflow. By carefully weighing these considerations and creating a detailed plan for robotic integration, you can harness the power of robotics to improve your operation and achieve your business goals.

What people are saying

Are you ready to start with industrial robotic arms?

You can find many used robots for sale in the current marketplace. Therefore making the right choice is important, contact a team of experts with a long history in robotic automation. As a result, working with us include but is not limited to proof of concept, engineering, integration, training, and programming. See also Industrial Used Robots for Sale