Robotic Assembly Solutions

The robotic assembly is ideal for tasks demanding speed, precision, and accuracy. Car manufacturing robots or assembly line robots are the most common robotic arms in the car industry.

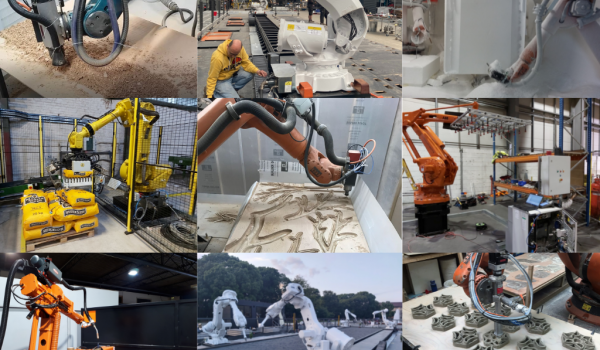

Robotic Assembly Customised Solutions

Experts in industrial automation and robotics integration provide customised automation systems. Please see below for an overview of robotic assembly lines.

Painting Robots

These Robots distribute paint evenly and efficiently.

Robotic Welding

Consistency and repeatability of the welds

Handling Robots

Improve production planning and reduces overtime

Robotic Milling

Reduce Operator Intervention and Minimise Risk

What Industries are using Assembly Line Robots?

The robotics industry is versatile, with the ability to provide small to large industrial robots. Consequently, the payload of each robot varies according to the application and the specific part to be handled.

Car Industry

In the car industry, assembly line robots are extensively used for automation purposes. For example, painting, welding, milling, cutting, and handling automotive components.

Food Industry

The food industry uses special types of robots that comply with sanitary requirements. Therefore, these robots require food-safe components, and hence, stainless steel is commonly used since it can withstand caustic cleaning chemicals. Additionally, robots must comply with food-safe lubricants. Some robot manufacturers have developed “gloves” that cover the robot, enabling extreme sanitisation processes.

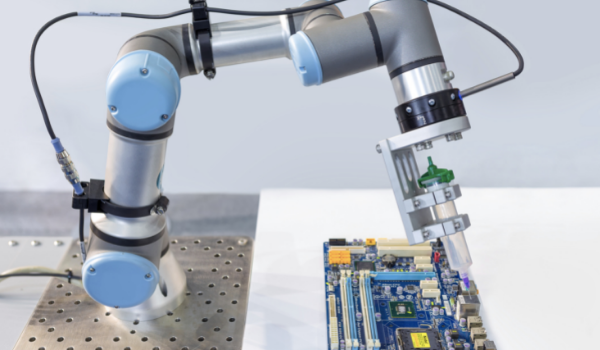

Electronic Industry

In the electronic industry, small robots that work alongside the staff or alone on assembly lines are used, to handle small and fragile electronic components. However, a cleanroom robot may be required to maintain the cleanliness of the assembly line.

The three main areas where assembly integration had been widely used are:

- Automotive components

- Computers and consumer electronics

- Pharmaceuticals and medical device assembly

Assembly robots can include vision systems and force sensors. Vision systems, therefore, reduce or eliminate the need for precise item location. Moreover, these sensing technologies together make a robot assembly line cost-effective for even relatively short production runs.

Benefit adopting industrial robot

Others assembly robot applications are Aerospace Industry, Marine Industry, Agriculture, Appliances & Consumer Goods, Building Products, and Energy Devices.

Some of the benefits of adopting assembly robot integration are:

- Reduce Operator Intervention

- Minimise Risk,

- No need for Product Handling

- Less Product Damage,

- Minimised operational failures

- Reduced Equipment Maintenance

- Optimised Operational Performance

Customised Automation Packages

Phoenix provides robot automation solutions for all car manufacturing and other industrial applications. It is recommended that you contact a system integration company before purchasing equipment for new projects. This can help reduce automation risks. For more information on robot statistics click here.

Top Most Common Manufacturing Applications

- Spray Painting Robots

- Robotic Assembly Lines

- Palletiser Robots

- Robotic Milling & Cutting

- Robotic Welding

- Material Handling Robots

- Robotic Palletising

- Dispensing Robots

Robot Integrator for car manufacturing robots

Always consult with a robot integrator. They can guide you not only on what other equipment to buy but also on where to get it. Robot integrators can assist with the integration of welding automation. For example, they can help with the integration, guide you on where to buy an affordable robot, assist in the integration of the control systems, and provide after-sale support. It is the whole automation package. Phoenix has extensive experience with automated painting and can help you overcome challenges with paint finishing throughput, consistency, and quality.

Are you ready to build a robot cell?

We build partnerships with our clients and we provide Customised car assembly line robot automation packages. As robot integrators, we understand the importance of delivering projects on time.

Phoenix has extensive experience in automated painting and can help you overcome any challenges